Industrialised construction in Data Centres

Italsan pipes offer maximum safety and guarantee in Data Center cooling applications and UPS generator power supply, being able to prefabricate modules for direct installation on site.

Who we are

We are a leading company in the manufacture and distribution of plastic piping system solutions and pipes, with extensive experience in the market, specialised in offering high quality products and advanced technology for various markets, including the Data Centre sector.

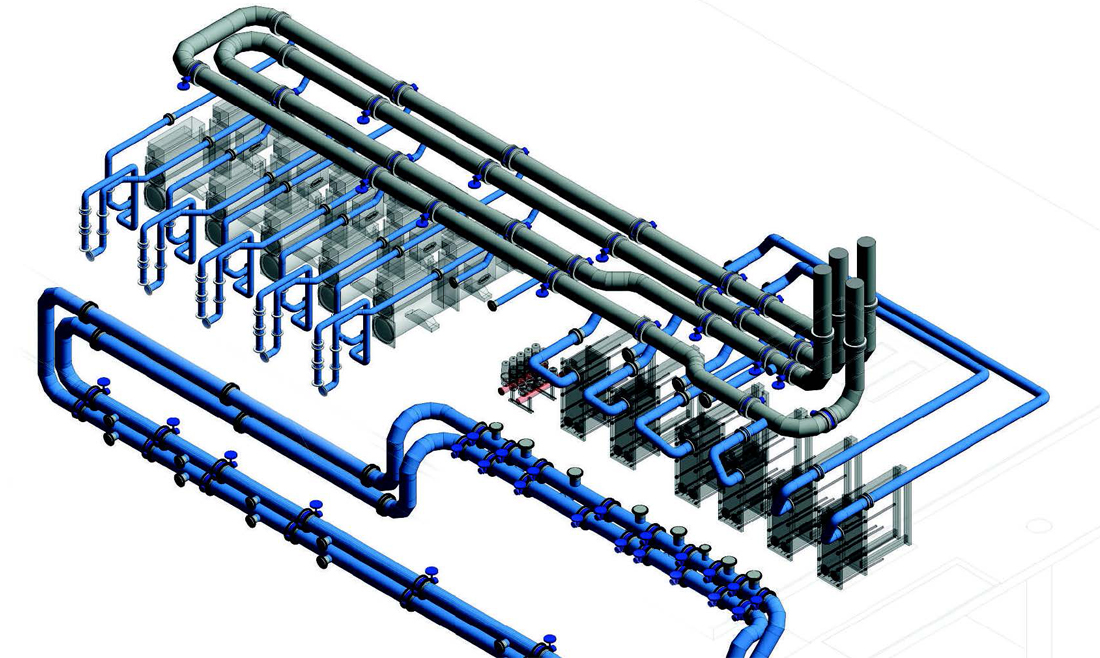

These systems cover different types of installations: from mission-critical cooling circuits such as cold production, distribution to FanWalls, distribution to RDHx, Direct Liquid Cooling circuits, and hydrocarbon transfer circuits to power generators.

We have a production centre specialising in modular construction, where collectors and modules are prefabricated and then assembled on site. This approach makes it possible to optimise the production process, minimise project execution costs, efficiently manage waste and improve energy efficiency during execution.

Our expertise in Data Centers

Advantages of our industrialized construction for Data Centres

We introduce an industrialised construction model applied in the area of air-conditioning installations in Data Centres, which offers the following advantages:

Savings

Reduction of error margins and associated cost overruns.

Control and efficiency

Improve process efficiency and optimise resources.

Flexibility

Adaptation to the design and needs of the client.

Quality

A unique and excellent product.

Sustainability

No waste generation.

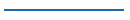

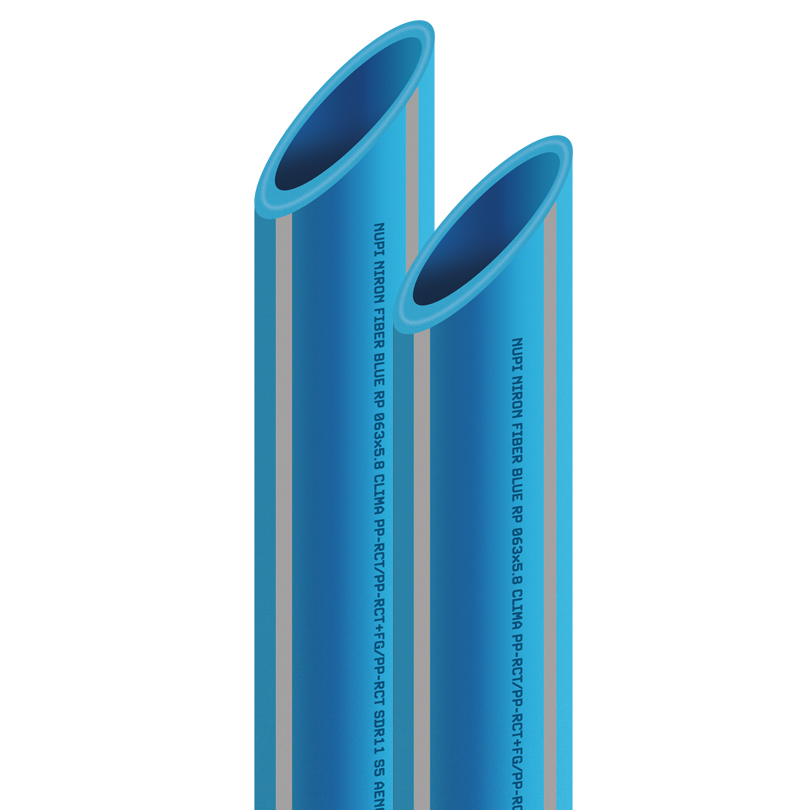

Types of pipes according to applications in a Data Centers

Pipelines are an essential element in the air-conditioning installations of a Data Processing Centre and in the transfer of hydrocarbons. Depending on the application, there are different types:

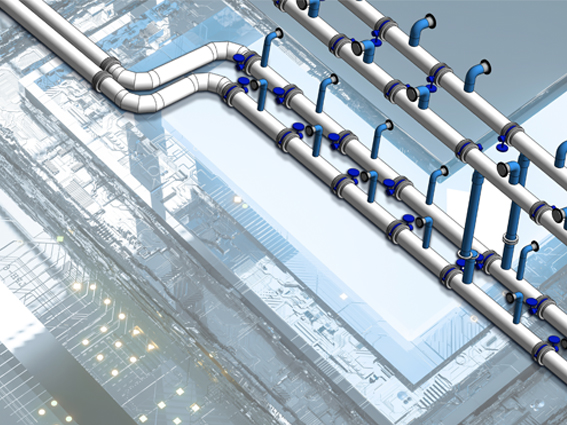

BIM Integration and Modeling Service

We rely on a qualified and professional team, with a high degree of knowledge of mechanical installations, working in a collaborative context based on the BIM (Building Information Modeling) environment. This environment allows us to have an exact reflection of the installation and it is here where the prefabricated construction system provides great advantages over the traditional “in situ” construction system.

- Libraries compatible with the different design software.

- Planning tables for the correct management of costs and planning of the work.

- Technical support in design and calculation.

- Transfer of Autocad project designs to BIM.

Construction details

The exchange of information with the planner, the engineering and the owner will be decisive for the correct implementation of the construction details.

Detailed study

• Choice of materials.

• Dimensioning of the installation.

• Detailed virtual construction with identification.

Compatibility between components

• Connections with other elements of the work.

Execution and production process

The exchange of information with the planner, the engineering and the owner will be decisive for the correct implementation of the construction details.

Optimisation of the solution

BIM modelling allows the project to be accurately previewed during the design stage in order to make the necessary corrections before arriving on site, optimising the number of accessories required based on a preliminary analysis in search of the best solution.

Spooling maps

During the production phase, simple spooling maps are generated with a clear and differentiated identification of each of the precast elements for their rapid implementation on site.

Reduced and greater risk control thanks to:

• Italsan guarantee.

• Decrease of connections in the field.

Drastic reduction of the material used, implicit sustainability.

Productivity and execution on site

Prefabrication allows us to increase the accuracy of planned construction times. The development of a project schedule from the delivery date eliminates the risk of delays due to material shipments.

The key points are Italsan’s excellent materials management and logistics, with coordinated shipments; consolidation of supplies; no need for on-site storage; reduced risk of delays; and increased accuracy in planned construction times.

Sustainability and efficiency

An industrialised construction system also offers a strong motivation, from a sustainability perspective, for reducing the carbon footprint by greatly reducing waste, being more efficient in materials and achieving more efficient transport.

Environmental Product Declaration (EPD)

The product is internationally certified as an environmentally friendly product based on Life Cycle Assessment.

|

|

Sustainability seals

Present in numerous new building and refurbishment projects, adding value to sustainability labels such as LEED and BREEAM.

|

|

Quality seals

The quality guarantee of our products is reflected in the certificates obtained and tests passed in accordance with the standards required on the 5 continents.